Introduction: What We Offer

Proper padel court maintenance is essential for ensuring safe play, consistent performance, and long-term durability—especially for facilities that rely on high-quality systems such as artificial turf, steel structures, and tempered glass enclosures.

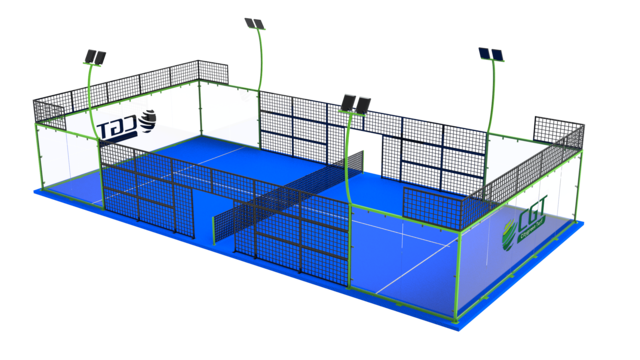

For those planning new installations or evaluating upgrades, you can explore our three padel court systems here:

[Super Panoramic Padel Court]

[Standard Panoramic Padel Court]

[Premium Panoramic Padel Court]

Preparing Your Padel Court

In addition to selecting the right system, ongoing maintenance plays a critical role in protecting structural integrity, preventing premature wear, and maintaining warranty compliance. This guide outlines the recommended daily, weekly, and monthly procedures designed for clubs, schools, sports complexes, and commercial facilities.

To support further planning and operation, you may also find these resources helpful:

[How to Choose Padel Court for Your Projects]

[Padel Court Installation Requirements]

Why Proper Maintenance Matters:

This guide provides court owners, facility managers, and maintenance personnel with clear and practical instructions for the proper use and upkeep of padel courts, including artificial turf, steel structures, and tempered glass components. Regular maintenance—through inspection, cleaning, and preventive care—is essential to ensure player safety, maintain structural integrity, preserve visual appearance, and extend the service life of the court while remaining compliant with warranty requirements.

Want the Full Maintenance Checklist?

Every facility is different, and maintenance needs can vary depending on climate, usage frequency, and court model. To help you operate your court safely and cost-effectively, we offer a free, complete Padel Court Maintenance Guide, including:

- Detailed daily–annual checklists

- Glass & steel care procedures

- Turf grooming & infill maintenance tips

- Safety notes and troubleshooting

- Region-specific maintenance recommendations

See how a professional padel court should look under daily maintenance

Contact Us to Get the Full Guide

If you'd like the complete maintenance manual or need expert support for your facility, reach out: sales@city-green.com

We're also happy to advise on installation, upgrades, or long-term service options.